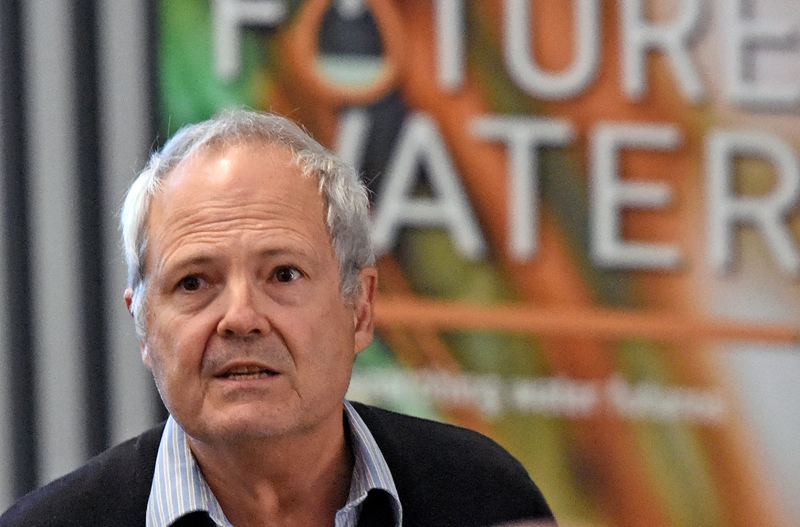

Thought Leadership Article by Jan-Hendrik Fourie, Senior Mechanical Engineer at Bureau Veritas South Africa

Boilers and combustion equipment can become an expensive problem for a company or home if assessments are not conducted on a regular basis to ensure performance levels are running at an optimum. Various catalysts can result in inefficient performance which can be avoided, thereby saving on the life cycle of the equipment and unnecessary costs.

This piece takes a deeper look into boiler and combustion efficiencies and provides insights into improved energy methods and thereby more environmentally sustainable practices according to BS 845 or ASME PTC 4.

The performance of boilers and associated combustion equipment depend heavily on several important combustion variables, including but not limited to:

- Air to Fuel ratios

- Stoker performance i.e. bed heights, grate speeds, flame locations, furnace pressures etc.

- Condition of boiler internals

- Effectiveness of draught group, i.e. fans and dampers

- Moisture content in fuel

- Coal particle size distribution

- Ash content in coal

- Water quality

- Air leakages

- Insulation

- Calorific values of the fuel

Over time, the combustion parameters change, and the accumulative effect causes a loss in combustion and boiler efficiencies.

Fire-tube boilers with coal-fired chain grate stokers have a design boiler efficiency of about 80%. Over time, the efficiency can reduce to 40% or less. There is a direct correlation between fuel consumption and boiler efficiency.

“When a boiler’s thermal efficiency is 40%, the boiler consumes double the amount of fuel to produce the same steam output. It is therefore crucial to regularly perform boiler and combustion efficiency assessments to determine if combustion variables are within specification,” says Jan-Hendrik Fourie, Senior Mechanical Engineer at Bureau Veritas Technical Center Africa. “It is essential to re-assess the boiler performance following major changes and modifications or when the fuel source has changed. Even if no changes or modifications were made, it is good practice to perform boiler performance assessments on an annual basis,” he explains.

Boiler owners can also benefit from independent boiler efficiency assessments after commissioning of a new plant or after re-commissioning of a modified plant to verify compliance with specifications or contractual obligations in terms of performance and efficiency.

It is recommended to involve a third party to perform independent boiler and combustion efficiency assessments. After boiler efficiency has been determined, further analysis and testing should be performed to determine the root causes of efficiency losses and steam production losses. For instance, if the boiler currently achieves a max of 10 tons per hour (tph) steam flow from a 21 tph boiler, investigations can be performed into why the boiler loses capacity and recommendations can be provided to restore efficiency and / or capacity.

How to calculate boiler efficiencies

Trusted third parties, like the Bureau Veritas Technical Center Africa assists clients by validating and optimizing their boiler performance. Clients leverage professional expertise in performance testing to detect design flaws, equipment degradation and take corrective actions to improve boiler performance.

There are two methods available to determine boiler efficiency:

- The first method is the direct method and the major plant inputs to this method are the fuel consumption and steam flow. Only if both before mentioned inputs are accurately measured, can this method be used.

- Alternatively, the indirect method is used to determine the boiler efficiency by measuring all the common losses on a boiler and then by subtracting all the losses from 100%, then one gets the boiler efficiency.

The common boiler efficiency losses (Lt gr) consists of the following:

- heat loss due to dry flue gas

- heat loss due to evaporation of water formed due to H2 in fuel

- heat loss due to evaporation of moisture present in fuel

- heat loss due to unburned combustible gases in the flue gas

- heat loss due to unburnt fuel in fly ash

- heat loss due to unburnt fuel in bottom ash

- heat loss due to radiation and other unaccounted loss

To quantify most of the efficiency losses, a flue gas analysis is performed. This entails performing flue gas measurements during online boiler testing. During the flue gas analysis, the following are measured:

- Boiler flue gas temperature

- Oxygen (O2)

- Carbon Dioxide (CO2)

- Carbon Monoxide (CO)

In the case of coal or other solid fuel firing, in order to quantify the heat loss due to unburnt fuel in the bottom ash and to determine the moisture content in the fuel, a fuel and ash analysis must be performed. Samples of the fuel (before combustion) and ash (during online boiler testing) are sampled while boiler testing is performed. After testing, the samples are sent to a lab to perform Ultimate and Proximate analyses on these samples.

The fuel and ash testing are a combination of Ultimate and Proximate analyses testing that is performed at Bureau Veritas Coal laboratories. The analyses define the following:

- Fuel constituents (i.e. Carbon, Sulphur, Nitrogen, Moisture, Ash etc.) based on mass fractions

- Ash constituents (i.e. Sulphide minerals, Carbonate minerals, Oxide minerals etc.) based on mass fractions

- Inherent and surface moisture in the fuel

- Total volatile matter

- Net and Gross calorific values of the fuel

- Carbon mass fraction (lost energy) in the ash samples

Once the online flue gas analyses and the fuel and ash analyses results are available, the boiler efficiencies can be calculated.

All results are processed using the techniques and correlations given in BS 845 parts 1 and 2, which is the standard for assessing thermal performance of boilers for steam, hot water, and high temperature heat transfer fluids. The same techniques can be used on various boiler designs and combustion types, i.e. Pulverised fuel, CFBC, chain grate, Natural gas, Bagasse, Peat, Black Liquor etc.

Trusted and tested process followed to assess equipment

For starters, documented information related to the boiler/s to be tested and a familiarisation process with all aspects of the particular boiler design and past reports and boiler modifications needs to be provided for assessment purposes. This is performed offsite. A plant visit, meeting the client and a plant walk down with the client follows to check out the operations on site.

Preferably, the boiler should be offline and open for an internal inspection to assess the conditions of the heat transfer components to be performed. This will be conducted on a separate date from the flue gas analysis because the boiler must be online for the latter tests to be performed.

At a time when the boiler is online (this can be the same day of meeting the client if the boiler will not be available for an offline inspection), an online flue gas analysis is performed, which entails measuring and recording flue gas properties at various boiler locations at different operating loads. Coal and ash samples are taken at the same time.

The Ultimate and Proximate coal and ash analysis is performed offsite at the Bureau Veritas laboratory.

Once all results are available, indirect and direct boiler efficiency calculations based on measured plant information are performed offsite.

Finally, a comprehensive report detailing the boiler and combustion efficiencies is compiled and recommendations are made to optimize boiler performance.

Benefits of regular boiler and combustion equipment assessments

There is a myriad of benefits to regular performance tests being conducted. These provide peace of mind for both clients and the employees on site.

- There is a great potential for savings on fuel cost by increasing the boiler efficiency. The potential savings on fuel cost significantly outweighs the cost of a boiler performance assessment and the return on investment could be as low as a few months

- Boiler efficiencies and areas of improvement to reduce fuel consumption are quantified and determined

- Implementation of our recommendations frequently gains steam capacities on boilers, in cases where there are capacity losses associated with low boiler efficiency

- Maintenance activities to improve on excessive boiler losses are identified

- Combustion adjustment requirements to conform to the Air Quality Act or other environmental regulations are indicated

- Compliance to specifications or contractual obligations after commissioning of a new plant or after the recommissioning of a modified plant can be verified.

- Implementation of recommendations may reduce boiler operating and maintenance costs.

In conclusion, it is recommended that boilers and combustion equipment are tested on an annual basis to avoid unnecessary complications and ensure maximum performances efficiencies. “At Bureau Veritas Technical Center, we support our clients by providing trusted third party independent testing, inspections and certifications of boiler and combustion equipment to enhance life cycle, prevent unnecessary maintenance and reduce costs whilst improving efficiencies and enhancing environmental practices,” Fourie concluded.

About the author

Jan-Hendrik Fourie has a decade-long progressive engineering career in the Power & Utilities industry. Armed with a Master’s degree in Nuclear Engineering underpinned by a Bachelor’s degree in Mechanical Engineering and a host of high-tech courses, this strategic engineering expert is an accredited Professional Engineer at the Engineering Council of South Africa (ECSA) and is registered at the Association for Energy Engineers (AEE) as a Certified Energy Manager (CEM). To date he has fulfilled several roles including Plant Care Engineer, Design Engineer and Senior Mechanical Engineer at Bureau Veritas South Africa and is a member of the Technical Center Africa team. He has a broad range of experience unique to pressure equipment such as boilers, piping, heat exchangers and pressure vessels, including condition monitoring of utility boilers.

As an avid supporter of nature and the environment, he appreciates the outdoors and trail running; cooking and watching Formula One and cricket. He relishes Sachin Tendulkar’s quote: “I just keep it simple. Watch the ball and play it on merit,” which he translates across his life: declutter and continuously develop oneself, always striving to add value in everything one does.

More news

- PART 2: CONCRETE IN THE DESIGN OF A UNIQUE LUXURY HOME IN GEORGE, SOUTH AFRICA

- PART 1: CONCRETE IN THE DESIGN OF A UNIQUE LUXURY HOME IN GEORGE, SOUTH AFRICA

- MVULE GARDENS, AFRICA’S LARGEST 3D-PRINTED AFFORDABLE HOUSING PROJECT

- PART 3: HARNESSING THE POTENTIAL OF HIGH SULPHUR FLY ASH IN CONCRETE PRODUCTION

- PART 2: HARNESSING THE POTENTIAL OF HIGH SULPHUR FLY ASH IN CONCRETE PRODUCTION