MasterLife CI 222 – Putting a Full Stop to Corrosion

Concrete erosion’s negative impact on South Africa’s coastal economies goes beyond the costly repairs its relentless damage visits on buildings and structures. Taking the correct precautions at the design stage of a structure is of utmost importance. If this stage is not given the appropriate focus, the design life as well as the sustainability of the structure will be significantly reduced.

Corrosion inhibiting admixtures can’t prevent corrosion, but it does slow down the chemical reaction and in doing so considerably delays the corrosion process. Jurese Venzke, head of marketing at Master Builders Solutions South Africa, explains why their dual action solution – MasterLife CI 222 – is an essential choice for all concrete structures built around South Africa’s coastline.

It works: how and why

“The best way to convey the power of this product is to describe our trials of this product in Kuwait. We cast cubes embedded with steel both with and without MasterLife CI 222, and some with competitor equivalent products. We set them in a wave pool for two years and the results are just incredible. Where both the control and the competitor were severely corroded, there was barely any corrosion on the cubes treated with MasterLife CI 222.”

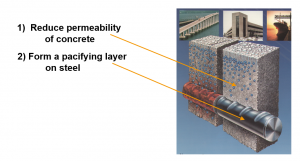

MasterLife CI 222 extends the service life of reinforced concrete by reducing the rate at which chlorides and moisture enter concrete, whilst also increasing sulphate resistance. Venzke explains that MasterLife CI 222 is a dual phase inhibitor, protecting steel’s passivity layer – which typically decays when the PH drops to 9 and under, and it strengthens concrete by creating a denser concrete matrix and acting as a pore blocker. This ensures that H2O , CO2 and chlorides cannot enter the concrete.” It also forms a protective layer on the rebar.

MasterLife CI 222 can be used in a variety of temperatures, and it protects reinforcement from corrosion even in cracked concrete. The solution is easy to apply and has no negative impact on the initial slump, the workability retention on fresh concrete, or setting time.

A natural solution for South Africa

Working with the product also sets it apart from its competitors in a major way. “Adding MasterLife CI 222 changes absolutely nothing of the mix’s rheology, and this means you don’t have to adapt your mix at all, unlike earlier products,” explains Venzke.

So successful has MasterLife CI 222 been that it has become a designated requirement for concrete mixes in Kuwait.

It certainly seems like a no-brainer for South Africa’s highly saline coastal conditions, and is a likely candidate for similar designation in South Africa. In the meantime, this is a product that simply puts any coastal concrete mix at an unbeatable competitive advantage.

Discover more about MasterLife CI 222 here

Contact Jurese Venzke directly at jurese.venzke@mail.mbcc-group.com or call her on +27 72 617 3613 to discuss your requirements and fulfill your order.

More news

- PART 2: CONCRETE IN THE DESIGN OF A UNIQUE LUXURY HOME IN GEORGE, SOUTH AFRICA

- PART 1: CONCRETE IN THE DESIGN OF A UNIQUE LUXURY HOME IN GEORGE, SOUTH AFRICA

- MVULE GARDENS, AFRICA’S LARGEST 3D-PRINTED AFFORDABLE HOUSING PROJECT

- PART 3: HARNESSING THE POTENTIAL OF HIGH SULPHUR FLY ASH IN CONCRETE PRODUCTION

- PART 2: HARNESSING THE POTENTIAL OF HIGH SULPHUR FLY ASH IN CONCRETE PRODUCTION