Facing perhaps the toughest economic conditions in living memory, South African businesses using diesel engines must refocus on preventative maintenance and quality remanufacturing.

This will ensure that their engines deliver optimal uptime and business continuity at a time when margins are being continually squeezed, says Andrew Yorke, operations director at Germiston-based Metric Automotive Engineering.

“Catastrophic failure of a diesel engine in these tough times can be fatal for the profitability of a project or even a company,” says Yorke. “More than ever, reliable and economical engine operation is now key to survival.”

He warns that cutting corners on maintenance programmes – which he has witnessed among many fleet operators – would inevitably lead to failures and costly unplanned downtime. An important aspect of preventative maintenance is regular oil sampling, for instance, which helps to identify issues such as coolant contamination and other factors that lead to high wear on engines and components.

“Companies need to empower their technical departments to ensure that best practices in fleet maintenance are applied,” he says. “This is not a function that can be devolved to a purchasing department.”

With the early warning that preventative maintenance provides, diesel engine users can plan ahead for timeous and cost effective repair or remanufacturing of large diesel engine components at experienced and well-equipped facilities like Metric Automotive Engineering. This world class service is particularly relevant with the Rand exchange rate contributing further to the high cost of importing new engines and components.

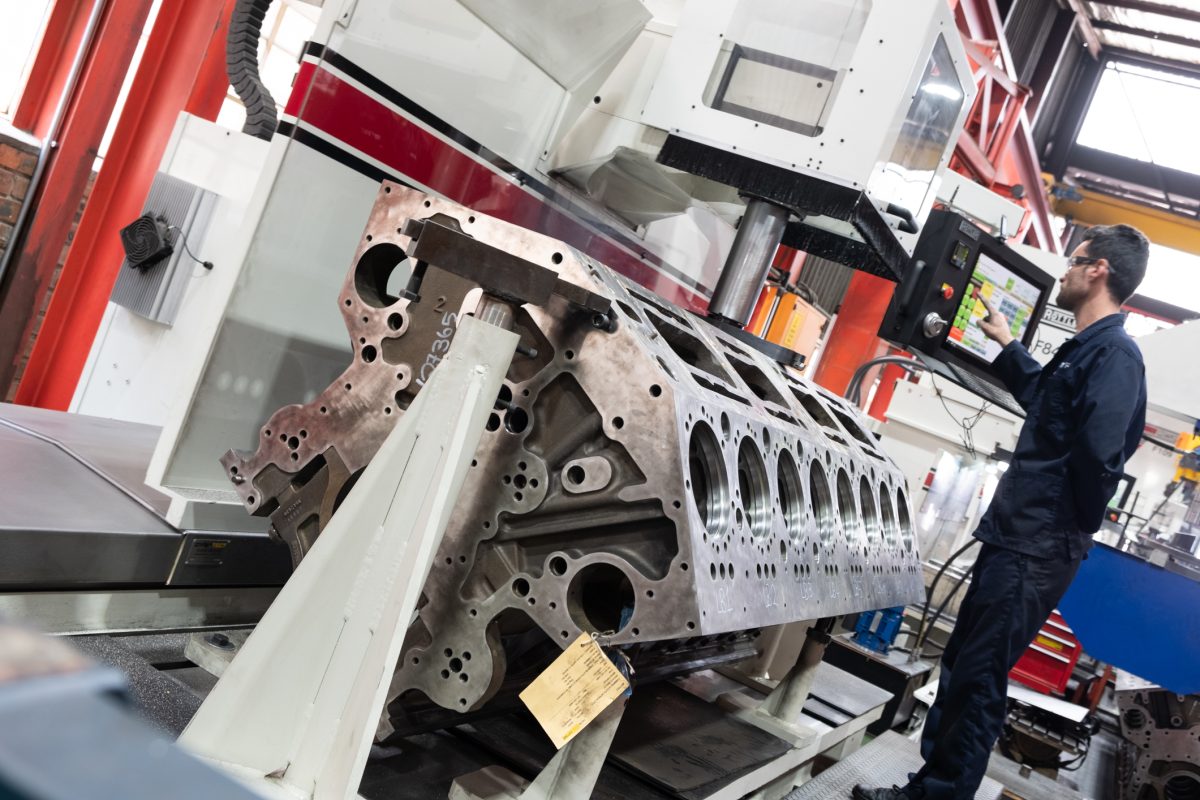

With 50 years of experience, this South African company refurbishes large diesel engine components and offers services such as cylinder head remanufacture, cylinder block line boring, milling, honing and boring. It also grinds camshaft and crankshafts, assembles engines and conducts dynamometer testing.

“Staying abreast of the latest technology means we are one of Africa’s leading crankshaft grinding facilities, with capability to grind shafts up to 4,7 metres long and up to two tonnes in weight,” says Yorke.

It deals with crankshafts from industrial compressors through to V16 locomotive diesel engines. The well-equipped workshop houses two state-of-the-art, three-axis CNC machines – the only ones of their type in Africa – for line-boring, surfacing and blue-printing of engine blocks up to six metres in length.

He highlights that remanufacturing large diesel engine components in South Africa currently makes even better sense because many replacement parts are no longer available ex-stock in the country. These have to be shipped in at extra cost, or even flown in if the situation is urgent.

Diagnosis and fault analysis on fuel injection systems is another benefit Metric Automotive Engineering offers its customers – through its sister company Reef Fuel Injection Services. This includes the remanufacturing of the latest generation of fuel systems, saving companies substantial costs on new components.

More news

- PART 2: CONCRETE IN THE DESIGN OF A UNIQUE LUXURY HOME IN GEORGE, SOUTH AFRICA

- PART 1: CONCRETE IN THE DESIGN OF A UNIQUE LUXURY HOME IN GEORGE, SOUTH AFRICA

- MVULE GARDENS, AFRICA’S LARGEST 3D-PRINTED AFFORDABLE HOUSING PROJECT

- PART 3: HARNESSING THE POTENTIAL OF HIGH SULPHUR FLY ASH IN CONCRETE PRODUCTION

- PART 2: HARNESSING THE POTENTIAL OF HIGH SULPHUR FLY ASH IN CONCRETE PRODUCTION