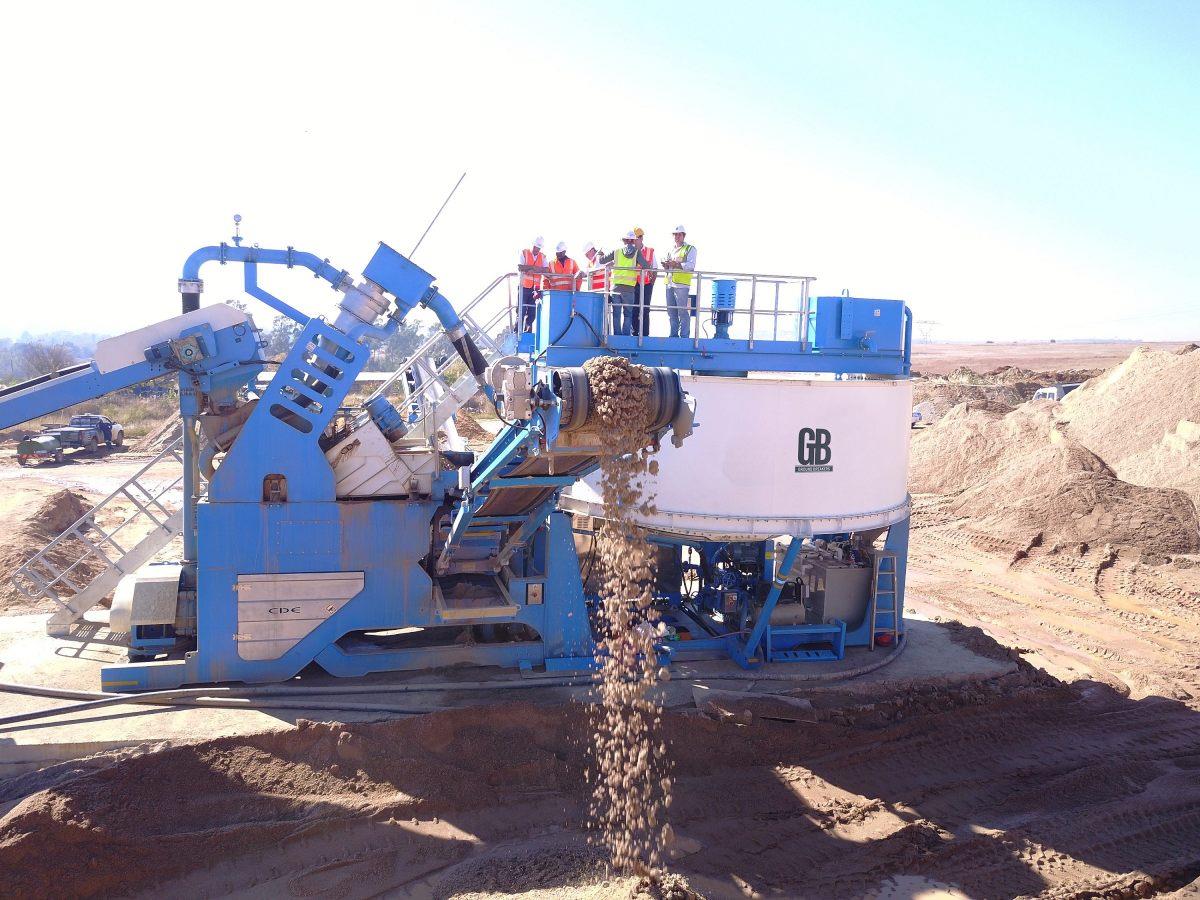

South African construction materials producer

Ground Breakers is using UK-based CDE’s Combo all-in-one wet processing and

water recycling system to enhance the quality of its products, while lowering

operating costs and ensuring greater return on investment.

The Combo has been in use at Ground Breaker’s

quarry in Lindley, Gauteng, for a few months, and has already garnered positive

results, and serves as a successful case study for other suppliers to emulate.

At a site visit to the quarry on 1 August, Ground

Breakers owner Johan Meintjes emphasised

that far from the company wanting to have the monopoly on the product in South

Africa, it was encouraging other suppliers to also pursue such technology, as

it would raise the quality of construction materials available to the market.

CDE already has three Combo plants in the country.

Ground Breakers began producing construction

materials at the Lindley quarry in November 2016 using a bucket wheel to

transform the quarry’s raw feed of decomposed granite into construction sand

and aggregates. The Combo is an upgrade of this system. Ground Breakers sought

to replace the bucket and wheel to counteract the loss of valuable materials to

ponds and excess moisture in the final products.

The quarry site had limited water sources and space

to put up a proper wash plant. Moreover, any silt dams took away valuable

mining area.

Ground Breakers also lost a lot of fines to the

settling ponds, wasting material that it could not sell without dredging the

ponds and reprocessing it through the bucket wheel.

After considering the site’s footprint and Ground

Breakers’ requirements, CDE presented the Combo as the ideal solution.

Combo has a capacity range of 50 t to 500 t and

boasts a modular design to combine feeding, grading, washing, water recycling

and stockpiling onto one compact chassis.

The Combo allows Ground Breakers to produce two

high-quality sands simultaneously from the raw feed, including plaster sand and

river sand, for a much faster ROI.

Previously, Ground Breakers had been producing only

one sand product, therefore, the technology has also expanded its product

offering, Meintjes indicated.

The Combo’s high-frequency dewatering screen

dewaters the material in one pass, removing the need for re-processing and

double handling.

Once the sand slurry with the silt material is

discharged from the hydrocyclones, it is delivered to the screen, which is

sized according to the customers’ specific capacity requirements.

This enables Ground Breakers to provide a product

above the two sand types mentioned earlier.

The Combo has advanced water management which

ensures that the final products are dewatered to an average 12% moisture,

making them ready for market straight from the belts.

As an added benefit, the fully integrated CDE

AquaCycle thickener allows for up to 90% of the process water to be recycled

directly into the system for near independence from freshwater supplies.

The more advanced Combo technology addresses the

shortcomings of the bucket and wheel system, such as the difficulty to control

the volumes of water required for accurate material classification, owing to

the limited capacity at the feed point.

It will also engender considerable cost savings for

Ground Breakers, as generally, it sells per tonne.

Her Majesty’s Trade Commissioner for Africa at the

UK Department for International Trade Emma Wade-Smith, OBE lauded the partnership between Ground

Breakers and CDE.

She noted that it was encouraging to see CDE

expanding its footprint into Africa and supporting producers with innovative

technologies.

Tthis would allow South African producers to be aligned with the latest technologies – even if the construction industry was not ideal at present, it would have quality products once demand picked up, would be ready to serve capacity, and moreover, could export products to other countries where there was demand. https://www.engineeringnews.co.za/article/uk-sand-washing-technology-used-to-great-effect-in-south-africa-2019-08-02