As South Africa’s depressed economy is further hammered by the Covid-19 lockdown, large diesel engine owners can be thankful that the country retains world-class diesel engine component remanufacturing facilities.

Key sectors like rail, mining, power generation and marine transport rely on large, hard-working diesel engines, according to Andrew Yorke, operations director at Germiston-based Metric Automotive Engineering.

“In times like these, customers are forced to take a far closer look at the cost of keeping these assets operational,” says Yorke. “The quality remanufacture of large diesel engine components is an ideal way of doing this, as it offers considerable savings over new replacement.”

The local remanufacturing option now makes even more sense as the global pandemic fuels exchange rate volatility and disrupts some cross-border supply chains.

Unprotected imports

“There has been a regrettable trend toward the unprotected importation of remanufactured diesel engines, which threatens the vital remanufacturing element of our engineering sector,” he says. “The worsening economic conditions are likely to highlight the benefits of using local expertise and services.”

While purchasing decisions tend to be driven by the upfront cost, he warns that the right choice of remanufacture can be the difference between future success and failure. In many cases, diesel engines are mission-critical to business sustainability, so their reliability should be of paramount concern to owners.

Designed for remanufacture

“Customers must ensure not only that they get a competitive price for remanufacture of large diesel engine components, but that their service provider has the necessary skills and equipment – coupled with a quality system meeting international standards,” he says. “Original equipment manufacturers design their components to be remanufactured several times, but this must be done to their exacting specifications.”

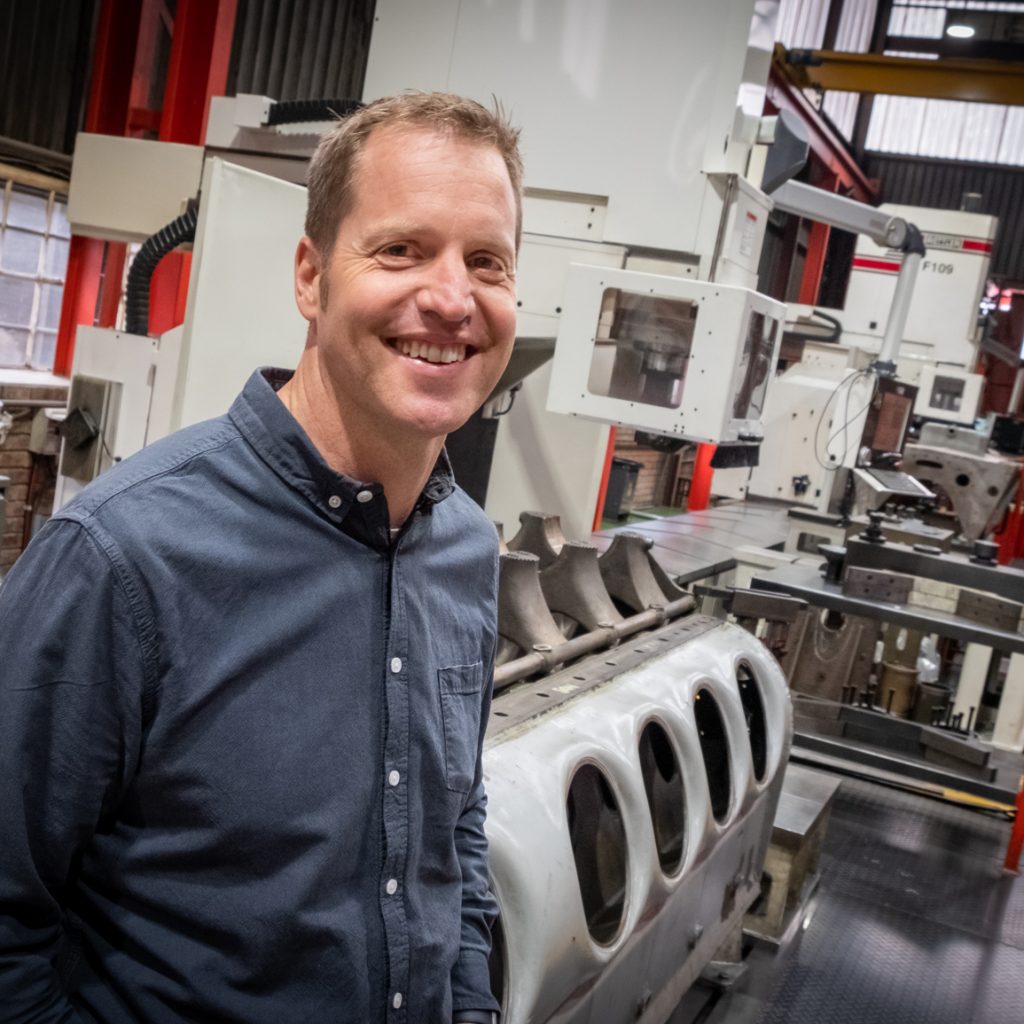

This quality is ensured by Metric Automotive Engineering, as the most comprehensively equipped diesel engine component remanufacturer in the country. Its facilities keep abreast of the latest technology and trends, with capability to handle large diesel engine components. With one of the leading crankshaft grinding facilities in Africa, it can grind shafts up to 4,7 metres long and up to two tonnes in weight.

“This allows us to grind crankshafts from industrial compressors right through to the V16 locomotive diesel engine,” says Yorke. The workshop also includes two state-of-the-art, three-axis CNC machines – the only ones of their type in Africa. These perform line-boring, surfacing and blue-printing of engine blocks up to six metres in length.

Yorke says it is time that South Africa’s high-value diesel engine component remanufacturing capability was recognised as a strategic national asset, which also contributed environmentally to the effective ‘recycling’ of engines and their components.

More news

- DOK-ING’s innovative electric mining equipment unveiled at ElectraMining

- CONCOR’S MASTERY IN FAST TRACK PROJECT IMPLEMENTATION UNDERSCORED BY SAFETY AWARD

- PROMINENT SEA POINT HOTEL REFURBS WITH REHAU

- CONCRETE ROOF TILES USED FOR WALL CLADDING ON COASTAL HOME

- THE GREENEST RESIDENTIAL DEVELOPMENT IN AFRICA?